Albacomp EA Ltd. offers a comprehensive manufacturing service for surface mount (SMD) and through hole (THT) components. Our production base is technologically flexible and we are able to assemble all types of components, from 0201 size SMD components to QFP and BGA/uBGA encapsulated integrated circuits, with high quality and great experience. Our typical batch size per production is between 20 and 2000 pieces, but we also produce prototypes.

Tin paste application

Tin paste is applied to PCB panels using a stencil printer. The automatic printers enable homogeneous, high-precision paste application and also have a built-in SPI (paste inspection) function, so that only flawlessly paste-coated PCBs can be loaded into the paste applicators.

SMD implantation

SMD insertion is performed with new Panasonic and Samsung Full Vision Pick & Place automatic insertion machines. The enormous advantage of the Pick & Place system is its extreme flexibility in terms of component packaging. The integrated circuit can be delivered in tube, reel or tray form, so that machine placement is possible in all cases.

- Accuracy: 50um

- PCB size: 50mm x 40mm – 420mm x 390mm

SMD soldering

After SMD insertion, high quality soldering is done in a REHM 9+3 zone or HELLER 7 zone convection reflow oven or vapour phase soldering station, which can produce a wide range of heat profiles to meet today's requirements.

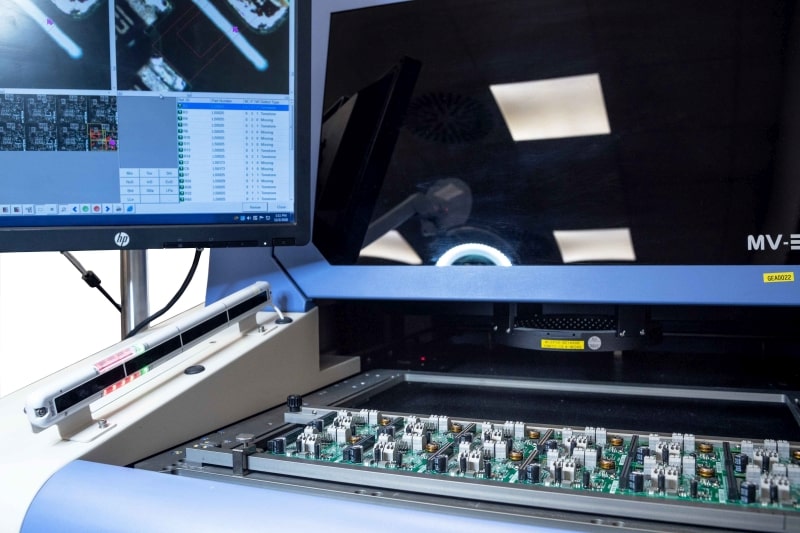

SMD control

Microscopic visual inspection and repair of soldered joints is carried out by staff with many years of experience. Precise, accurate repairs are made possible by ERSA and JBC repair workstations and JBC heat gun with adjustable temperature, a wide range of accessories, and component-adaptable repair workstations.

Final inspection according to IPC-A-610

In addition to the microscopic inspections between production and after SMT assembly, we also perform 100% visual final inspection of all our products to ensure high quality. The final inspection is carried out by IPC-A-610 specialists with valid examinations.